A Case Study : Epoch HVLS 16-ft Fan By Falco eMotors Inc.

Report No. 041420-02

Problem:

-

The Micro Plastic industry are one of the leading manufacturers of high quality plastic injection component, Tooling and subassemblies to Automotives Sport Equipments, Power Tools, Appliances, Electricals, Electronics, Telecoms & Heavy Engineering.

-

The high temperature of the shop in summer also affects the machine. The temperature rise of the machine also affects the operators of the tors of the shop

-

As the plastic moulding is done on the injection moulding, continuous operation causes the molding fixtures to heat up.

-

Due to high ambient temperatures, heat stress, heat stress can affect workers.

-

In order to maintain and reduce the temperature in the shop, they decided to install HVLS fans in their shop.

Solution:

- Epoch 2.0, 16-ft 04 Fans was installed with the following specifications ;

- Motor: Epoch 2.0;

- Coverage Area: 12000 Sq. Ft. (1,114 Sq. m);

- Speed: 95 RPM;

- Peak Power: 1.1kW/1.5 hp;

-

Epoch 2.0, 16 ft diameter fan becomes most popular with amazing airflow and airflow efficiency.

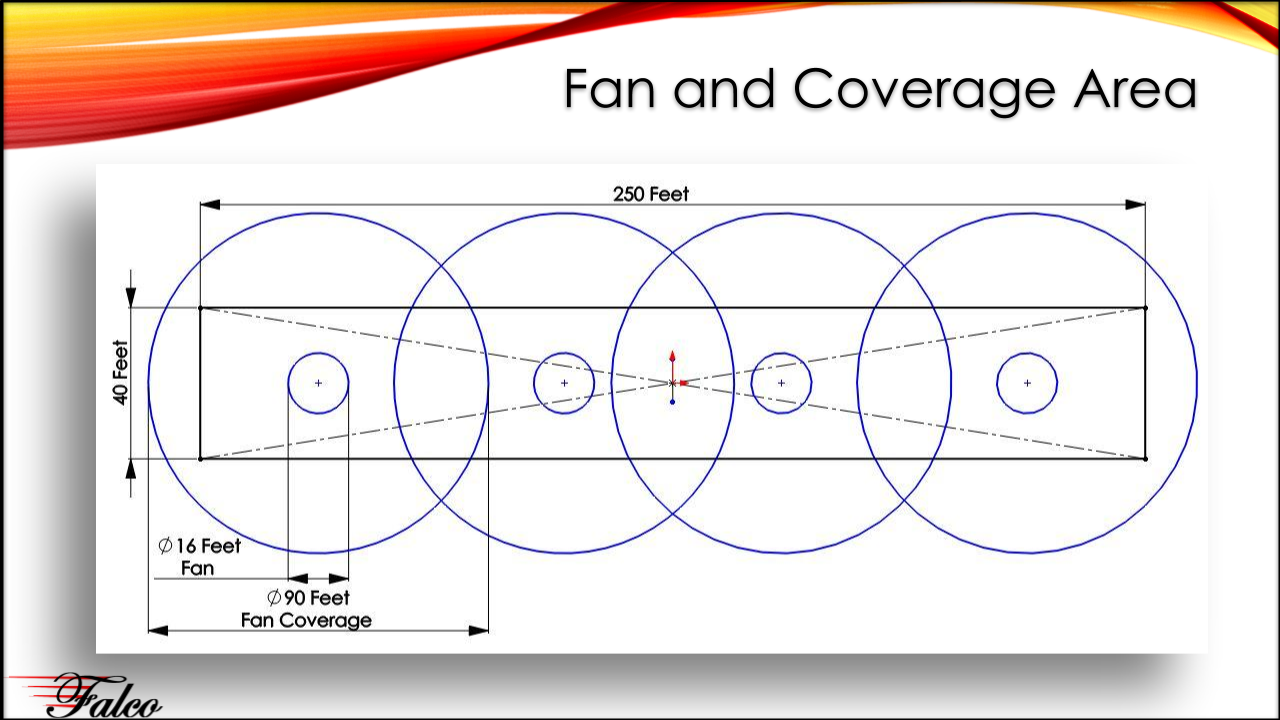

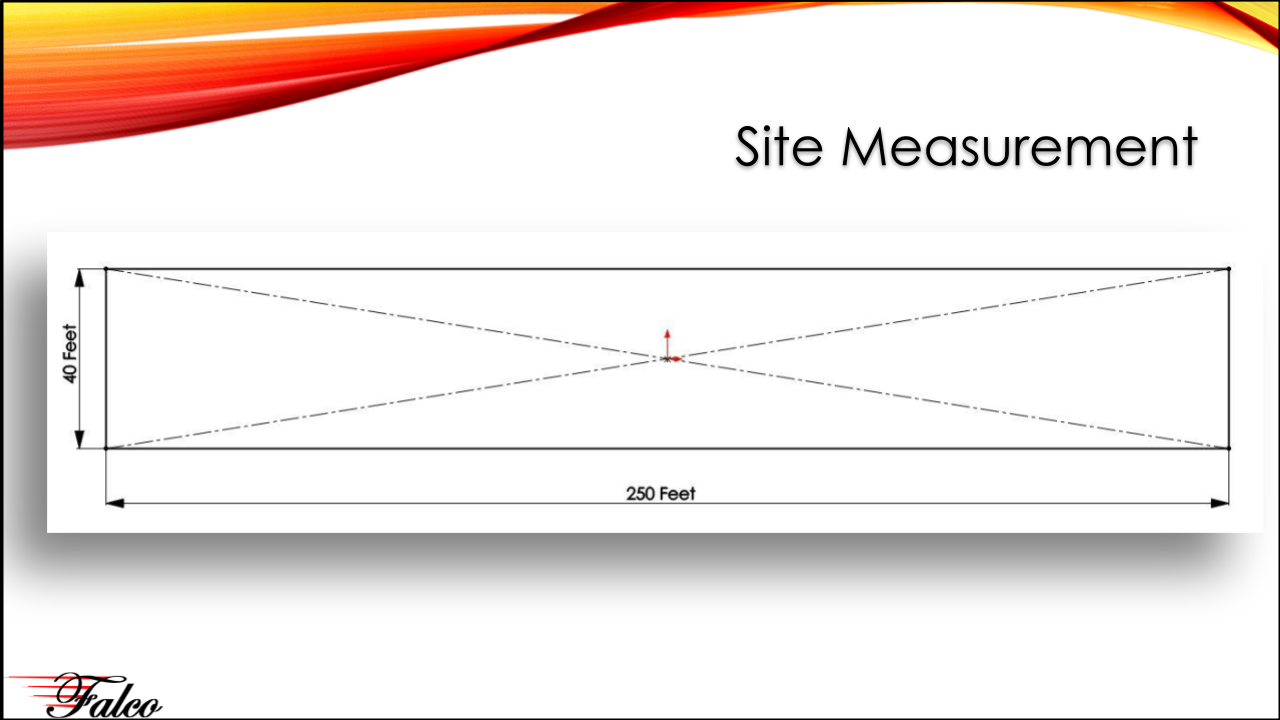

Site Survey:

A site survey is mandatory before any HVLS fan recommendation. The survey revealed the following dimensions:

- Total Area: 250 ft X 40 ft = 10,000 Sq. ft.

- Floor to Ceiling Distance: 22 to 25 ft

- By a rule of thumb distance/1.5 gives us the approximate fan diameter.

- In this case, we chose to go with a 16-ft fan.

Fan and Coverage Area:

Test Reports:

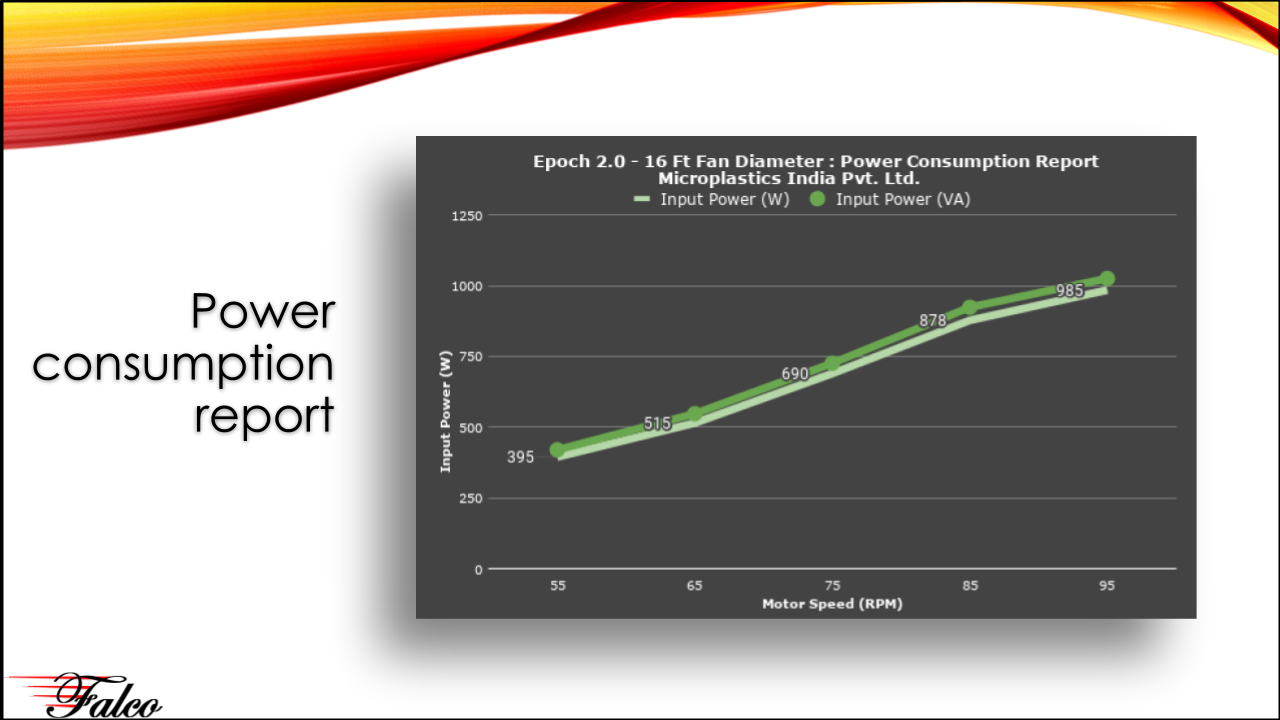

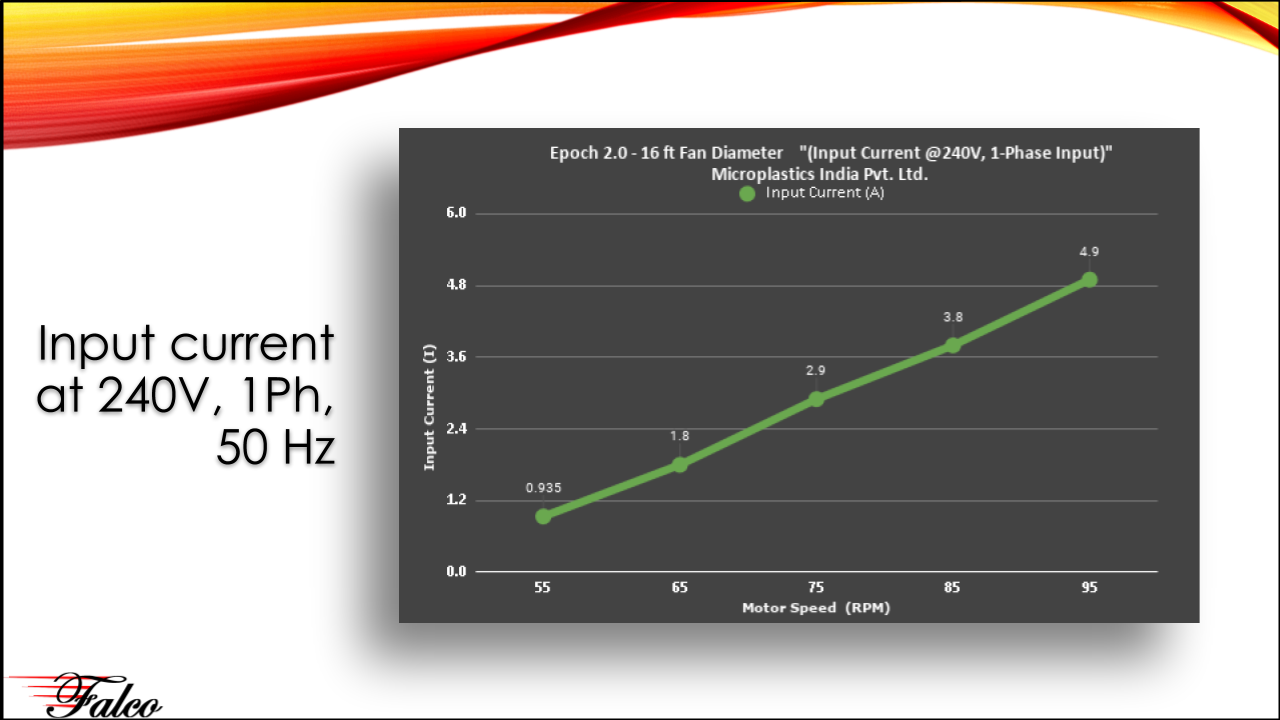

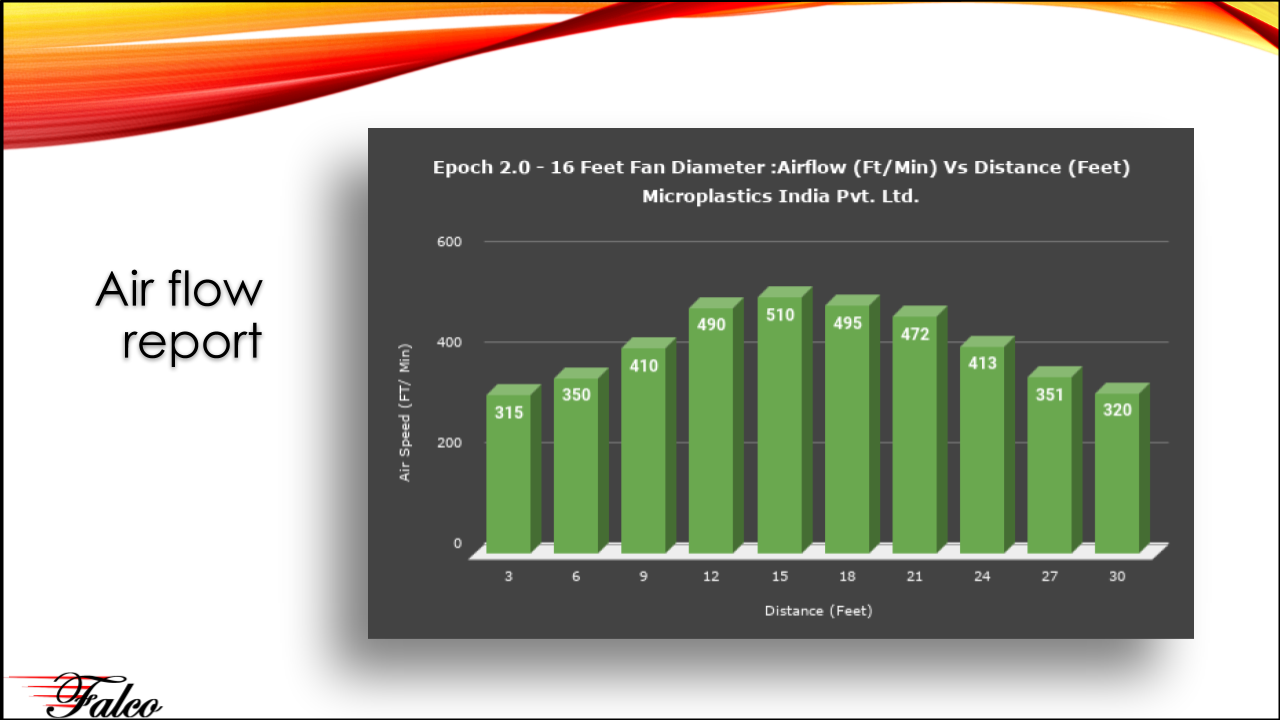

Three test reports are collected for each fan installation as follows:

- Power Consumption Report;

- Input Current Report;

- Air Flow Report.

Those reports are shown for this site:

Power consumption report captures the real as well as apparent power. Epoch HVLS fans are the only fans in the world to have active power factor correction and unity power factor. Therefore the Watts (Real Power) and VARs (the apparent power) are almost the same. The power has been captured at 55, 65, 75, 85 and 95 RPM. Power drawn at those speeds are 395, 515, 690, 878 and 985W respectively. The chart above also shows trend lines generated using Excel for real and apparent power to take into account any measurement errors as fan power consumption can be modeled by well known equations.

The input current is also measured at 55, 65, 75, 85 and 95 RPM. Input current is recorded as 0.935, 1.8, 2.9, 3.8 and 4.9A respectively. The input voltage varied from 240 to 244V during the measurement.

The airflow is measured from the center of the fan and is recorded at every 3-ft distance. Values were recorded upto 30-ft from the center of the fan. The values were respectively, 315, 350, 410, 490, 510, 495, 472, 413, 351, 320 ft/min at distances of 3,6,9,12,15,18,21,24,27, and 30-ft respectively.

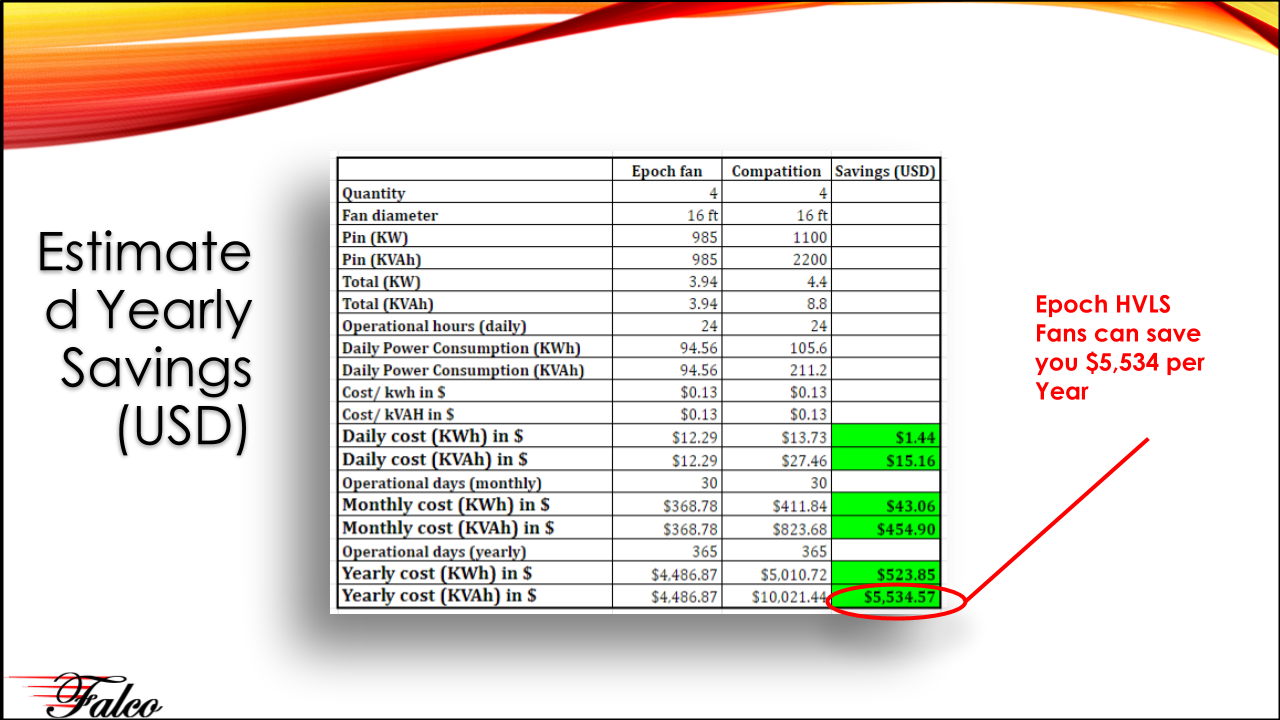

Estimated Yearly Savings while Using Epoch HVLS Fans

Epoch 16-ft fan was compared against Indian HVLS fan Manufacturer. Based on their data sheet, daily, monthly and yearly power consumption and costs were calculated. An Epoch HVLS fan will save the end user anywhere from $523 to $5,534 per year over any competitive brands because of its unique technology.

Finished Installation:

Above is the picture of the finished installation.